Critical Dimensions Matter

The Problem

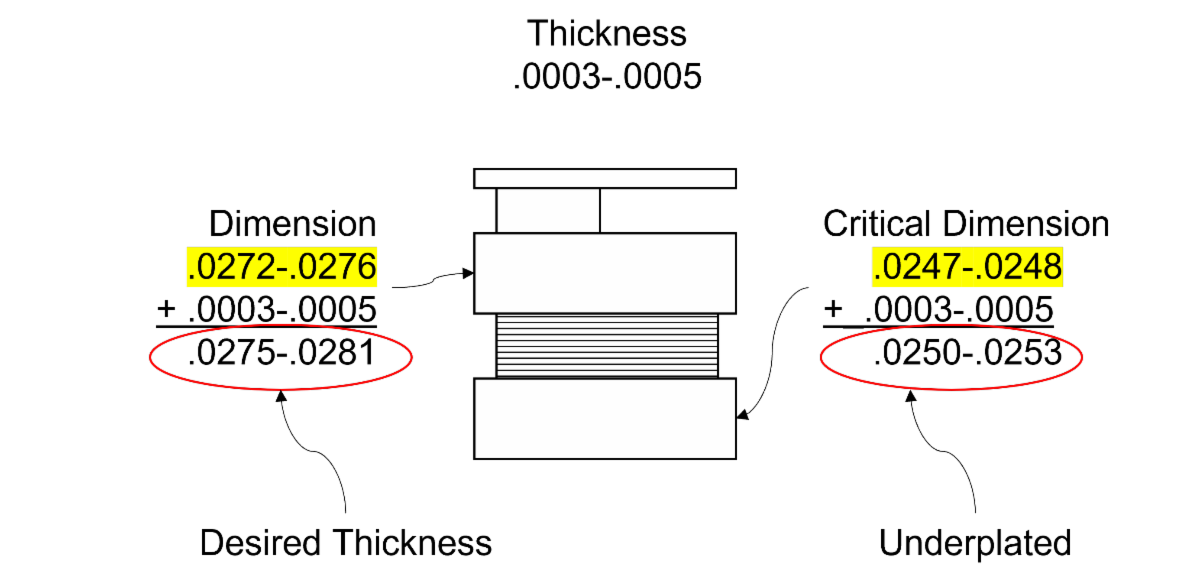

A customer sends a part to be metal finished. They require a thickness of .0003-.0005. However, the customer does not inform the finishing company that there is a critical dimension on one section of the part that is different than the other sections. When the finishing company properly applies .0003-.0005 to the entire part, the critical dimension area does not have sufficient finish. Electroplating does not deposit on all surfaces evenly.

The Solution

It is essential that customers inform the finishing company of:

- The areas of critical dimension on the part.

- Areas that need to be measured with a micrometer.

This will enable the finishing company to treat the entire part, mask the non-critical area, and then plate the area of critical dimension.

Quality Assurance

Metal finishing quality depends upon the customers providing complete information about the dimensions and critical areas of a part.