Our Process List

Our Processes

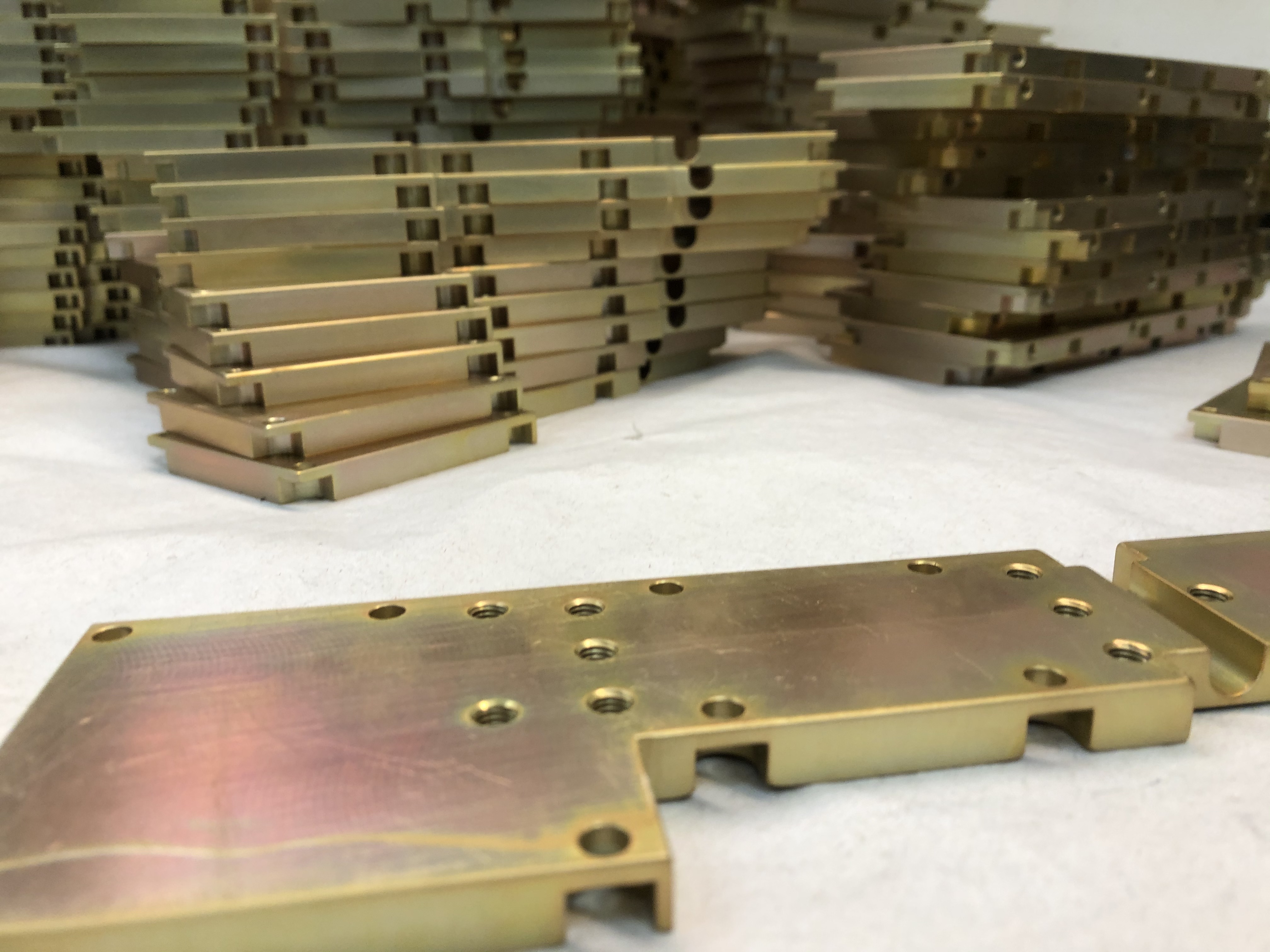

Plated Finishes

Precious Metal Plating

Silver plate. Bright and matte finish available.

Gold plate. Both hard and soft finishes available.

Zinc Plating

Lustrous zinc coatings can be produced over ferrous and non-ferrous metals for increased eye appeal.

Copper Plating

Primarily used as an undercoat and also for selective carborizing.

Bright Nickel Plating

Ideal as an ornamental finish for sales appeal where cost is a predominating factor.

Electroless Nickel

Assures absolute uniformity of plate inside and out regardless of irregularities of shape. RoHS compliant available.

Sulfamate Nickel

Ideal for aircraft and nuclear applications but has many industrial applications.

Tin

Used on items that come in contact with foods or in electrical field.

Bright and matte finish available.

Tin-Lead, 60/40, 90/10

Applied to parts that have to be soldered after assembly.

Our Processes

Surface Treatments

Aluminum Conversion Coatings

This coating provides a better bond and more durable protection for paint than more expensive oxide forming processes on aluminum and its alloys. RoHS compliant available.

Titanium Cleaning & Acid Etching

This is an Aerospace requirement from the OEMs like GEAE for P4TF3. Alpha-Case removal.

Zinc Conversion Coatings

A finish for zinc, aluminum, copper, brass and bronze, which protects against corrosion.

Colors include clear, blue, yellow, olive drab, or black. RoHS compliant available.

Pickling

This is a process that removes oxides from the surface of various metals, such as steel or stainless steel.

Passivating of Stainless Steel

This is a process that removes the free iron from the surface of stainless steel.

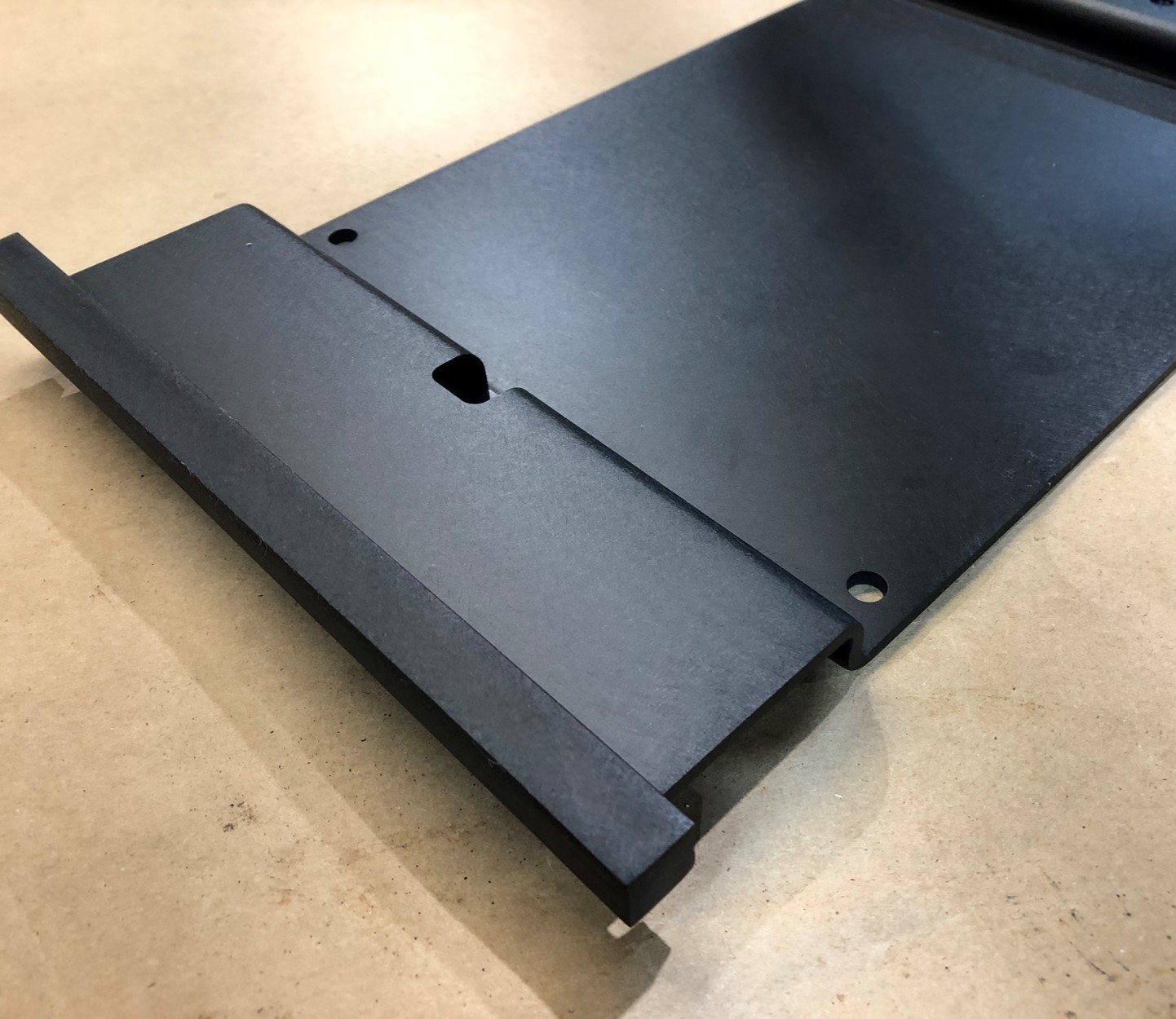

Black Oxide

This is a jet-black decorative finish for iron and steel. Has some corrosion inhibiting properties in it but is usually supplemented by a rust preventive oil. No dimensional change.

Our Processes

Anodizing

Sulfuric Anodize Type II

Provides oxide coatings for aluminum and its alloys.

Color finishes available: clear, black, red, blue, green, purple, gold, gray, and orange.

Hardcoat Anodize Type III

Sodium dichromate, nickel acetate, and hot water seals are available.

F.M. Callahan & Son

About Us

F.M. Callahan & Son, Inc. is a NADCAP and ISO 9001 certified electroplater, ITAR registered, serving you since 1910. We are a full service company with a 40,000 square foot state-of-the-art facility. We plate precious metals of silver and gold, electroless nickel, sulfamate nickel, zinc, copper, tin, and tin-leads. Our surface treatments include black oxide, pickling, passivating, conversion coating, and chromating.

We have exclusive relationships to process parts with the following companies:

Approvals

F.M. Callahan is certified to perform the following procedures

Specifications

Copper Plating - AMS 2418; MIL-C-14550;

Silver Plating - AMS 2410; AMS 2411; AMS 2412; ASTM B700; QQ-S-365;

Sulfamate Nickel Plating - AMS 2403; AMS 2424; AMS-QQ-N-290;

Electroless-Nickel Plating - AMS 2404; AMS 2405; AMS(MIL)-C-26074; ASTM B733;

Aluminum Anodic Coating - AMS 2471; AMS 2472; MIL-A-8625, Type II and Type III;

Aluminum Conversion - AMS 2473; MIL-DTL(C)-5541;

Acid/Alkali Cleaning - P4TF2; P4TF3;

Titanium Cleaning - P4TF3; S-421;

Black Oxide - AMS 2485; MIL-DTL-13924;

Gold - AMS 2422; MIL-DTL-45204;

Tin - AMS 2408; ASTM B545; MIL-T-10727

Zinc - AMS 2402; ASTM B633;

90/10 Tin Lead - MIL-P-81728;

60/40 Tin Lead - MIL-P-81728;

Passivation - AMS-QQ-P-35; ASTM A380; ASTM A967; AMS 2700;

Chem Film - AMS 2473, AMS 2477, MIL-DTL(C)-5541

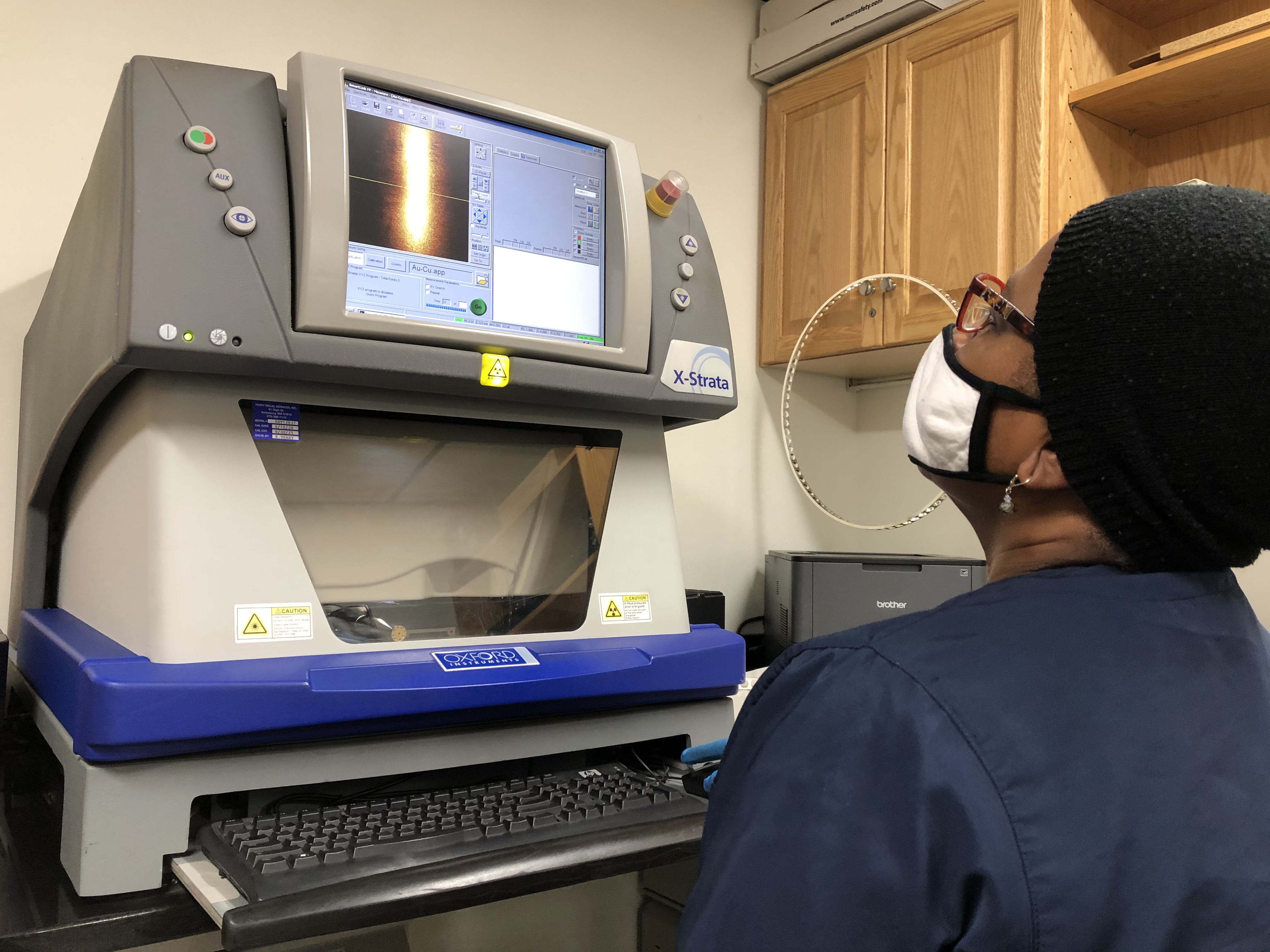

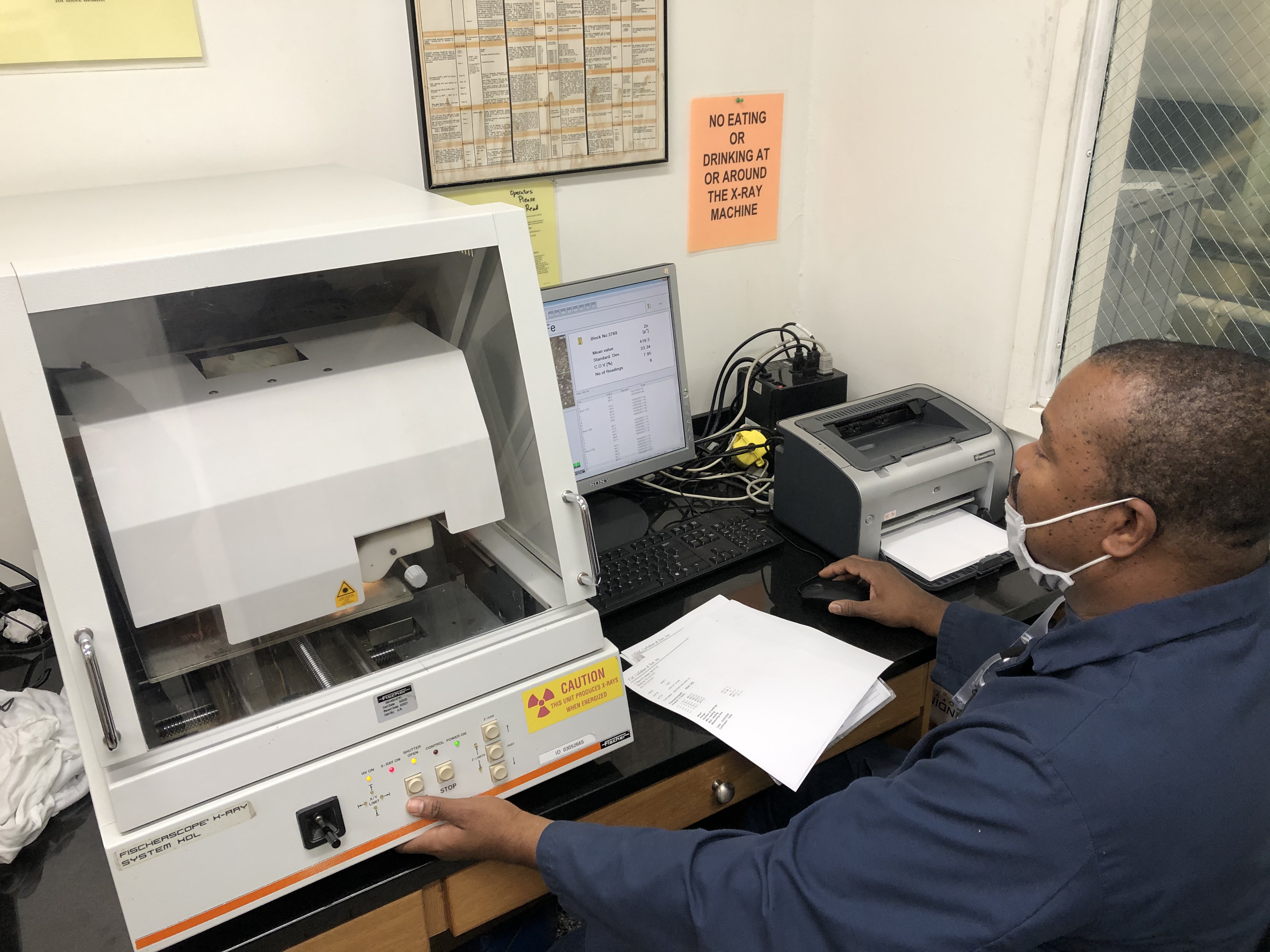

F.M. Callahan has a variety of tools to verify thickness

State-of-the-Art Testing

Oxford Instruments X-Ray

Fischer Scope X-Ray

Eddy Current Testing

Atomic Absorption Spectrophotometer Testing

Please enjoy our

Company Video

Team

Leadership

Eric Jacklin

President

Kevin Reynolds

Quality Manager

Tom Upton

Production Manager

Laura Sayball

Management Representative

Zekarias Neway

Technical Director